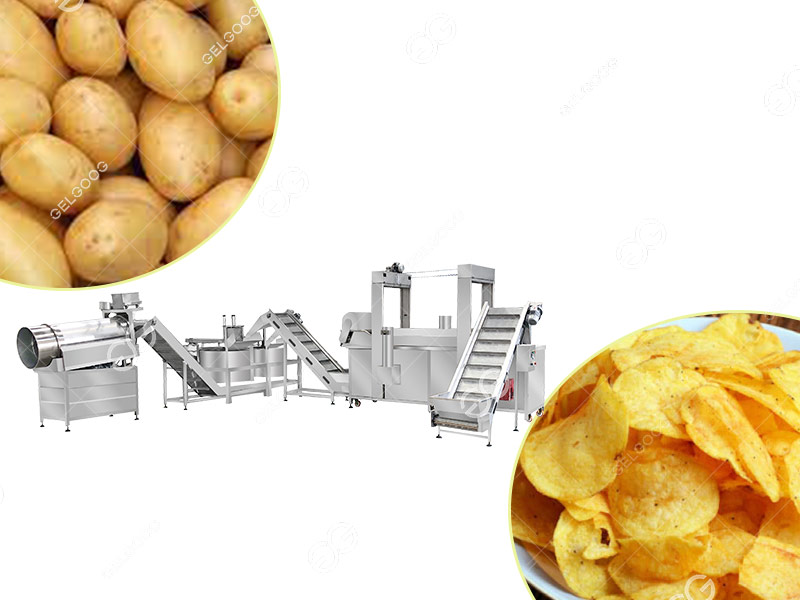

Because fried potato chips are crispy, delicious and suitable for all ages, they are loved by many people. Therefore, potato chips have also become an inseparable part of the snack market and have great profit prospects. Then there are many people who start potato chip processing business. So what machines are used to make potato chips? If you are interested in potato chip processing business, I hope this article can help you.

What Machines Are Used To Make Potato Chips?

The potato processing equipment manufacturers needed to make potato chips includes potato washing and peeling machine, potato slicers, potato blanching machines, potato dehydrators, potato chip fryers, potato chip deoilers, potato chip seasoning machines, and potato chip packaging machines. Processing Equipment.

Potato chips production process: lifting – cleaning and peeling – picking – lifting – slicing – rinsing – blanching – cooling – drying – frying – deoiling – picking – seasoning – packaging

Potato chips processing process and specific description of potato processing equipment

1.Elevator: The potatoes can be easily poured into the hopper manually, and the potatoes can be continuously and evenly lifted into the peeling machine through the conveyor belt, which saves time and effort, is convenient and durable.

2.Potato cleaning and peeling machine: After the potatoes enter the potato cleaning and peeling machine, cleaning and peeling can be carried out at the same time. Using the propulsion method of spiral blades and flowing water operation, automatic continuous cleaning and peeling can be realized, which can be used with production lines.

3.Picking belt: pick out defective or incompletely peeled potatoes, and transport them to the next process through mesh belt transmission.

4.Elevator: The selected materials can be continuously and evenly lifted into the cutting equipment through this equipment, saving a lot of labor and increasing production.

5.Potato slicer: easy to operate, high output, adjustable in thickness, and the finished product is smooth and uniform without breaking.

6.Rinsing machine: It is equipped with a bubble generating device to make the material roll, effectively remove the starch and impurities on the surface of the material, the floating matter can overflow from the overflow tank, and the sediment is discharged from the sewage outlet to achieve the purpose of cleaning.

7.Blanching machine: the heating part, the temperature is automatically controlled and set at will. The body is made of stainless steel, which meets the food hygiene standard.

8.Cooling machine: Potato chips will have a certain amount of heat after blanching, and there will be sticking together. Using air bubbles to roll up and down, imitating manual scrubbing, can quickly lower the surface temperature of potato chips and effectively prevent The material is blanched excessively, and the material is fully dispersed, which is conducive to the uniformity of frying. Finally, it is conveyed by the mesh belt into the next process for further processing.

9.Air-drying machine: The high-pressure wind of the fan cools the food and dries the surface moisture. The air nozzle is shaped like an air knife, which effectively increases the air volume and pressure, so that the moisture in the potato chips can be blown away or evaporated in a short time, effectively preventing When frying, the phenomenon of jumping oil and shortening the frying time.

10.Frying machine: The whole machine is made of stainless steel, which is durable and can control the temperature freely. Using electric heating, the thermal efficiency reaches over 95%, saving energy, equipped with a fully automatic oil filter to remove slag, there is no carbonized matter in the oil, the oil will not turn black, the service life is long, the fried potato chips are bright in color, taste good, and improve Product grade.

11.Deoiling machine: The fried potato chips are conveyed by the mesh belt and cooled rapidly by the high-pressure wind of the fan to blow off the surface oil. Blow off in a short time, the equipment is equipped with an oil pan, the oil that is blown off can be collected and reused through the oil pan, saving oil while making the potato chips non-greasy and better in taste, convenient for storage.

12.Picking machine: it is conveyed through the mesh belt to pick out defective or incompletely fried potato chips. It is convenient to pick, saves time and effort, and can work continuously.

13.Seasoning machine: Equipped with a lifting device and a hopper above the drum, the seasoning is evenly and continuously sprinkled into the drum, and the potato chips are seasoned and mixed through the rotation of the drum. Collection and reuse not only mix the ingredients evenly but also ensure the integrity of the potato chips, which is convenient and practical.

14.Fully automatic packaging machine: The whole machine realizes automatic production, from automatic feeding, automatic lifting, automatic weighing to automatic bag making and packaging without manual operation and error-free, powerful automatic data statistics function, recording the total package of each batch of production Quantity, qualified rate and single bag error and other indicators. And you can adjust the packaging speed, size, weight and other data through the touch-screen operation interface. The humanized design is convenient and practical, and the performance is excellent, saving you a lot of raw material and labor costs, and the return on investment is fast.

Have you understood the above potato chip processing machinery? Do you want to start a potato chip processing business? If you need to clean it, please contact us. We are a potato processing equipment manufacturer, and we can provide solutions for potato chip processing, please contact us as soon as possible.