Leafy vegetable processing is becoming more and more popular in today’s life, because fresh vegetables have a very short storage time, and many are processed into canned vegetables, frozen vegetables, etc. So, how do you make fresh leafy vegetables processing?

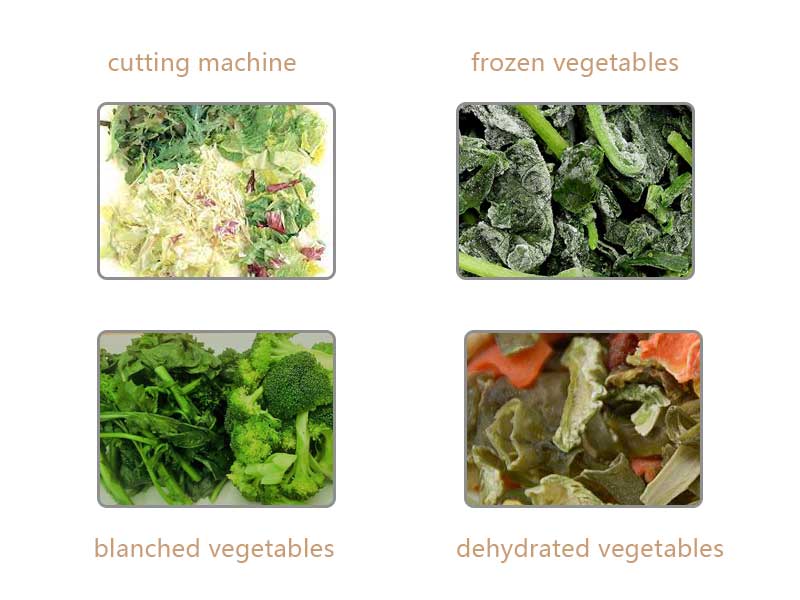

There are many processing methods of leafy vegetables processing: including vegetable washing, vegetable cutting, vegetable blanching, vegetable dehydration, vegetable freezing, etc., which are the most common processing methods. Vegetable processing companies typically process vegetables as described below.

vegetable processing industry

- Vegetable cleaning

The leafy vegetable washing machine is usually mainly based on the bubble washing machine. The dense bubbles generated make the leafy vegetables tumble in the water, and the water circulation system can realize the function of automatic water change. There is also a spray system on the slope of the washing machine, which can clean the vegetables for a second time, so that the vegetables are cleaner and the surface of the vegetables will not be damaged.

- Cut vegetables

Vegetables are cut using vegetable cutting machines, which are divided into different types, which can cut vegetables into cubes, strips, and shreds. Different specifications and different types of machinery can be customized according to the needs of vegetable processing

- Vegetable blanching

Blanching of vegetables Using a vegetable blanching machine, put the vegetables in and blanching at a temperature of 90 to 98°C for about 60 seconds, depending on the leafy vegetables. Blanching will shrink the leafy vegetables significantly, making grinding and filling easier. In addition, enzymes lose activity, making the quality of deep-frozen leafy vegetables less likely to deteriorate during long-term storage.

- Dehydration of vegetables

Leafy vegetable dehydration can remove the water on the surface of the vegetables. The vegetable air dryer or the vegetable vibration water filter can be used to remove the surface water of the washed vegetables or blanched vegetables. If you want to make dried vegetables, you need to use a vegetable drying room, and you can set the working time and temperature of the drying room.

- Vegetable frozen

Leafy vegetables processed and frozen can be frozen using plate freezers, freezer tunnels or spiral freezers. Freezing time depends on product size and may take several hours. In a plate freezer, the product is cooled by a coolant. In a freezing tunnel or spiral freezer, freezing is performed by circulating air at -35°C with an air velocity between 3 and 5 m/s.

The above is the way of processing leafy vegetables. If you want to start a leafy vegetable processing business, you can contact us, we will provide you with solutions and all the equipment introduced in the article.