The vegetable washer uses the bubbles generated by tap water to remove the sediment and a large number of pesticides and hair and other impurities on the vegetable surface, which reduces the consumption of harmful substances on the vegetable surface and reduces the harmful substances on the vegetable surface. Harm to the human body. The vegetable washer of vegetable washing line is made of food-grade stainless steel. The vegetable washer itself is safe and does not cause any pollution to vegetables. The cleaned vegetables can be eaten directly. It is a practical and safe machine.

The role of vegetable washer

1. Decomposition of pesticides, hormones and toxins: Ozone has strong oxidizing properties, rapidly oxidizing pesticides and decomposing harmful substances.

2. Sterilization and disinfection: single atoms in ozone have strong permeability, which can quickly destroy the cell walls of bacteria and viruses, and achieve the purpose of sterilization and disinfection.

3. Fresh-keeping and deodorizing functions: Vegetables washed with ozone water or blown with ozone gas can prolong the fresh-keeping period by 2-3 times.

The benefits of vegetable washer

If we use daily clean water, it may take a long time to remove pesticides and chemicals on the surface of vegetables. Because it is the surface of the vegetable that grows for a long time. If it is for the vegetable processing industry, this is an inadvisable approach. Because it will consume a long time and a lot of labor. The vegetable washing machine can solve the above problems. It can wash hundreds of kilograms or even thousands of kilograms per hour, which greatly improves the efficiency of vegetable cleaning. Reduce waste of time and labor costs.

The purpose and usage scenarios of vegetable washer

The vegetable washer is mainly used to clean the stem and leaf vegetables such as lettuce, celery, spinach, cabbage, etc., and to clean, peel and polish the potato radish of the root material. You can also clean apples, tomatoes, peppers, eggplants, cucumbers, strawberries, dragon fruit, durian and other fruits.

The vegetable washer can be used in central kitchens, food processing plants, pickle processing plants, farms, seafood processing plants, salad processing plants, etc.

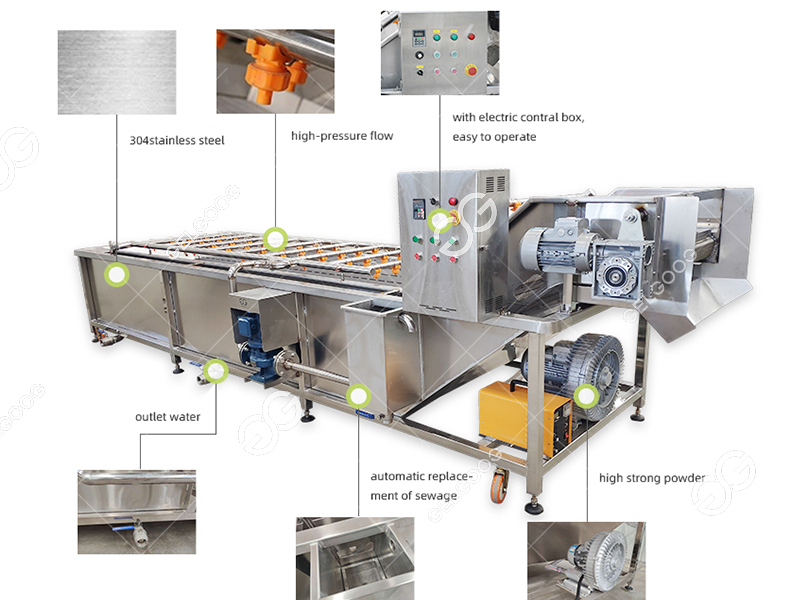

The principle of vegetable washer

The working principle of the vegetable washer is roughly as follows: first, all the vegetables that need to be cleaned are put into the sink, and under the action of high-pressure water flow and strong air bubbles, they are fully dispersed, rolled, cleaned and transported. The sediment on the surface of the vegetables will fall off and settle into the bottom isolation bin, preventing re-pollution caused by turning up and backflow. The sundries and insects washed from the vegetables will float on the water surface and then be collected by the mesh, and the water overflowing the sink will be discharged from the water tank and enter the nylon bag. After the vegetables are cleaned by the vegetable washer, they are cleaned by spraying, and then sent out through the conveyor belt. There is a blowing device at the end of the conveyor belt, and the sundries that have not been completely cleaned are blown off.

Summary from the above: The vegetable washer is a safe, reliable and very practical machine for vegetable processing. It can thoroughly clean the impurities on the surface of vegetables. If you are interested in this machine, you can write a comment or leave a message. I will answer your questions and problems.