Fast food industry, group catering industry, nutrition and health of snack food and group logistics have become an important part of people’s daily diet. Market demand is the driving force behind the development of the industry, and the catering industry will become the main market for the processing and distribution of clean vegetables. Many industry practitioners want to do clean vegetable processing, but do not know what equipment to buy. Next, the editor will take you to see what equipment is required for the vegetable cleaning and processing production line, and how to use the fruit and vegetable processing line?

- Vegetable cleaning and processing production line equipment

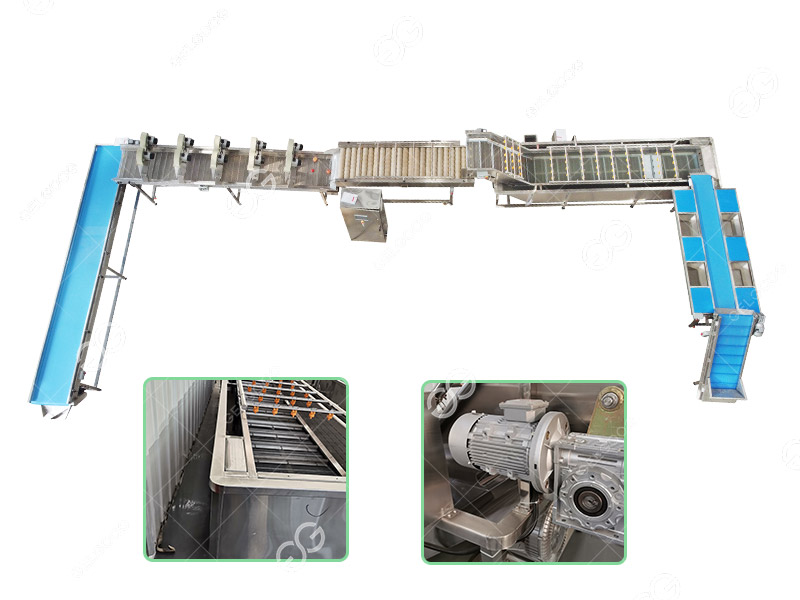

The equipment required for the vegetable cleaning and processing production line mainly includes belt conveyors (for picking vegetables), cleaning equipment (mainly including bubble cleaning machines suitable for leafy vegetables and most fruits and vegetables; brush cleaning machines suitable for root vegetables; suitable for cutting Eddy current washing machine for vegetables), blanching machine, air drying equipment or centrifugal drying machine, multifunctional vegetable cutting machine, vacuum packaging equipment, etc.

- Precautions for the use of vegetable cleaning and processing production line equipment

1.The water quality must meet the hygienic requirements. During the working process, the water inlet pipe and the spray water pipe are always supplied with water, so that the sewage in the water tank is gradually replaced;

2.Soak the vegetables in the pool for manual grading and screening, divide the products into different grades according to the specifications, and carry out preliminary cleaning to remove some sundries and yellow leaves. It should be noted that the soaking time of vegetables in water should not be too long, generally not more than 2 hours, to prevent softening and loss of pigment;

3.The size of the clean vegetables is one of the important factors affecting the quality of the product. The condition of the blade is also closely related to the preservation time of the cut vegetables. Clean vegetables cut with a sharp knife will keep for a long time, and the clean vegetables cut with a dull knife have a large cut surface and are easy to cause discoloration. Therefore, it is necessary to reduce the number of cuttings as much as possible, and the cutting knife is required to be made of stainless steel, and the blade body is thin and the blade is sharp;

4.The dehydration time of the centrifugal dryer should be appropriate. If the dehydration is too much, the clean vegetables will be easily dried and withered, but the quality will be reduced;

5.After the clean vegetables are cut and exposed to the air, wilting and discoloration of the cut surface are likely to occur, so packaging should be carried out as soon as possible to prevent or mitigate these adverse changes. The packaging material and thickness are generally selected according to the type of clean vegetables, which can be packaged by modified atmosphere or vacuum. Choose appropriate packaging materials to keep the clean vegetables in the bag with a minimum of aerobic respiration, resulting in a low oxygen, high carbon dioxide environment, thereby extending the shelf life of the clean vegetables.

As long as the clean vegetables are processed by selecting appropriate raw materials (variety and maturity), controlling unfavorable physiological and biochemical reactions, maintaining appropriate temperature, and carrying out dehydration and sterilization, high-quality clean vegetables that satisfy consumers can be obtained.

Our company always regards technological innovation and professional service as the driving force to maintain the development of the enterprise. Since its establishment, the company has improved its research and development capabilities by continuously digesting and absorbing the advanced technical experience of vegetable cleaning and processing in the same industry at home and abroad, and designed and developed personalized vegetable cleaning and processing solutions according to different processing needs of customers.